Changing or growing will always entail complexity.

- Igh2

- Sep 17, 2024

- 2 min read

Updated: Sep 20, 2024

Although sewing technology has reached advanced limits, there are still ample opportunities in Latin America to improve both productivity and quality in manufacturing.

Investments in the sewing room depend on the optimal configuration of our assets, such as inventory, machinery, buildings and logistics. Each of these areas must maximize its efficiency to optimize the performance of fixed and current assets.

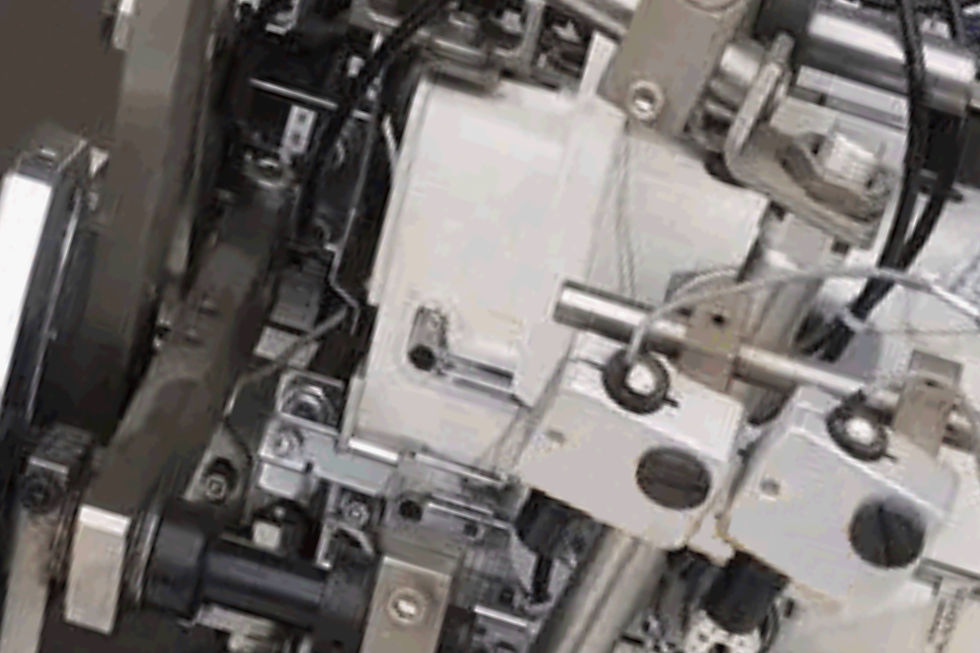

As for machinery, its efficiency is directly related to the proper configuration and the balance between investment costs and the quality of the final product. Achieving this delicate balance requires complex decisions based on technological sewing principles and other specific factors, such as the quality of the final product, its possible price, the target cost and the duration of the project, whether new, expansion or improvement.

While many of these factors are known to the project owner, it is in the area of sewing technology where most questions arise and where reliable sources are lacking. A data analysis reveals that 80% of machinery imports in Latin America consist of single-carry straight machines, overlockers, collar seam stitchers, bar tackers and buttonhole machines with buttonhole variants. This approach, while beneficial to machinery manufacturers and distributors, can increase costs for those who use them.

Looking at a typical factory, it is likely that only these common machines are used. To give an example, for an efficient production process of 1000 high quality shirts, with long sleeves, breast pocket, collar and fused cuff, 55 sewing machines would be required, of which only 15 would be single-transport straight machines. The rest would involve specialized productivity setups and automata.

What happens when a factory relies exclusively on straight, single bottom feed machines? The result is increased costs and decreased quality due to over-reliance on operators, long training curves, increasing rework and scrap, etc.

In order to address these challenges, I have created IGH2, a space where sewing machine manufacturers and suppliers can find a reliable source of consultation and knowledge to make informed decisions. Please feel free to contact us; we will be happy to hear about your project or need.

Comments